Cryogenic Top-Entry Fixed Ball Valve utilizes a fixed ball design, where the ball is rigidly supported at both ends, minimizing operating torque and ensuring stable sealing under high pressure and thermal stress. Key components are made from specially selected cryogenic-grade materials (e.g., stainless steels like 316L, 304L) that retain toughness and prevent embrittlement at ultra-low temperatures. Seals are designed for extreme cold, often utilizing resilient materials like PTFE or reinforced PCTFE, or specialized metal seating.

These valves provide bubble-tight shut-off, high flow capacity (full port option), and exceptional reliability in demanding services like LNG (Liquefied Natural Gas), liquid nitrogen, oxygen, argon, ethylene, and other cryogenic fluids handling. The combination of easy maintenance (top-entry) and robust performance (fixed ball) makes them a critical and dependable solution for cryogenic systems.

Class 150, Class 300

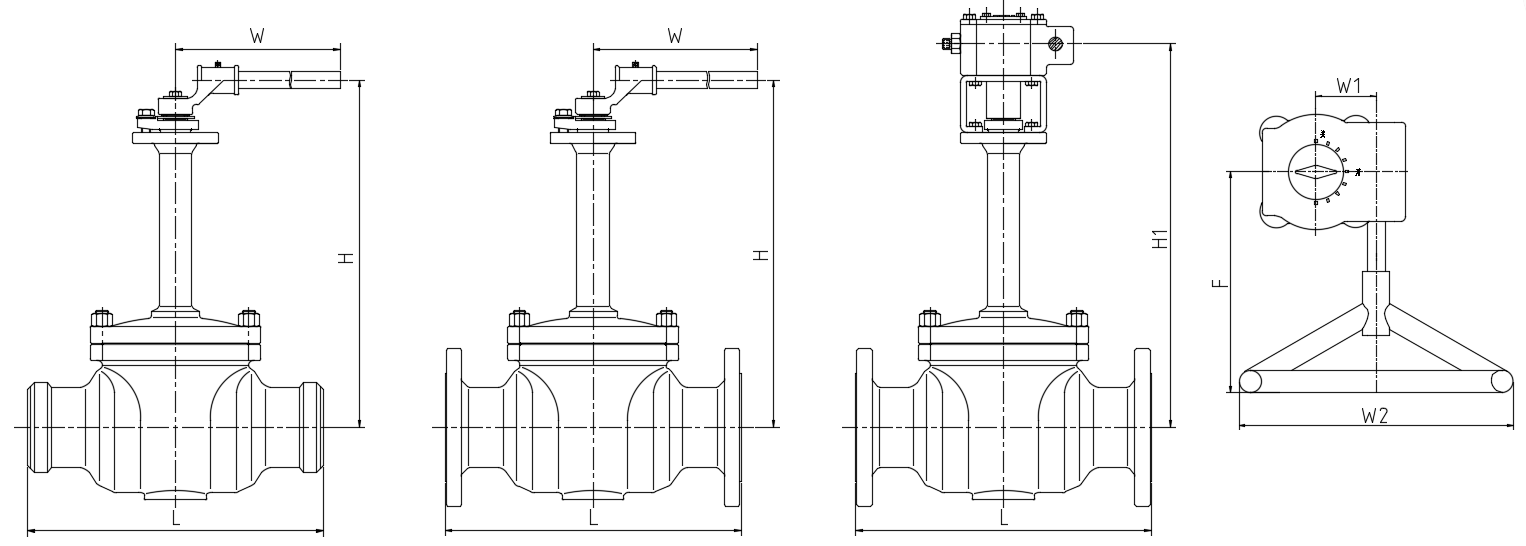

Specs | øD | L(RF) | L(BW) | H | H1 | W | W1 | W2 | F |

DN50 | 50 | 292 | 292 | 383 | 460 | 350 | 40 | 150 | 97 |

DN65 | 64 | 330 | 330 | - | - | - | - | - | - |

DN80 | 76 | 356 | 356 | - | 520 | - | 55 | 350 | 119 |

DN100 | 100 | 432 | 432 | - | 547 | - | 69 | 500 | 159 |

DN150 | 150 | 559 | 559 | - | 693 | - | 105 | 700 | 230 |

DN200 | 201 | 660 | 660 | - | 768 | - | 130 | 750 | 275 |

DN250 | 252 | 787 | 787 | - | 912 | - | 211 | 400 | 335 |

DN300 | 303 | 838 | 838 | - | 1000 | - | 263 | 650 | 388 |